"Kevin Barrett" (kevinbarrett)

"Kevin Barrett" (kevinbarrett)

03/07/2015 at 02:32 • Filed to: MAINTENANCE, MAD PROPS, CONTINENTAL, AVIATION, FABRICATION, SCHOOL, C-85, O-190, ENGINE

13

13

9

9

"Kevin Barrett" (kevinbarrett)

"Kevin Barrett" (kevinbarrett)

03/07/2015 at 02:32 • Filed to: MAINTENANCE, MAD PROPS, CONTINENTAL, AVIATION, FABRICATION, SCHOOL, C-85, O-190, ENGINE |  13 13

|  9 9 |

In my fourth quarter at South Seattle's Aerospace Maintenance Technology school, I just finished giving an ancient motor a makeover, rebuilding everything around the engine except the engine itself, and I learned quite a bit.

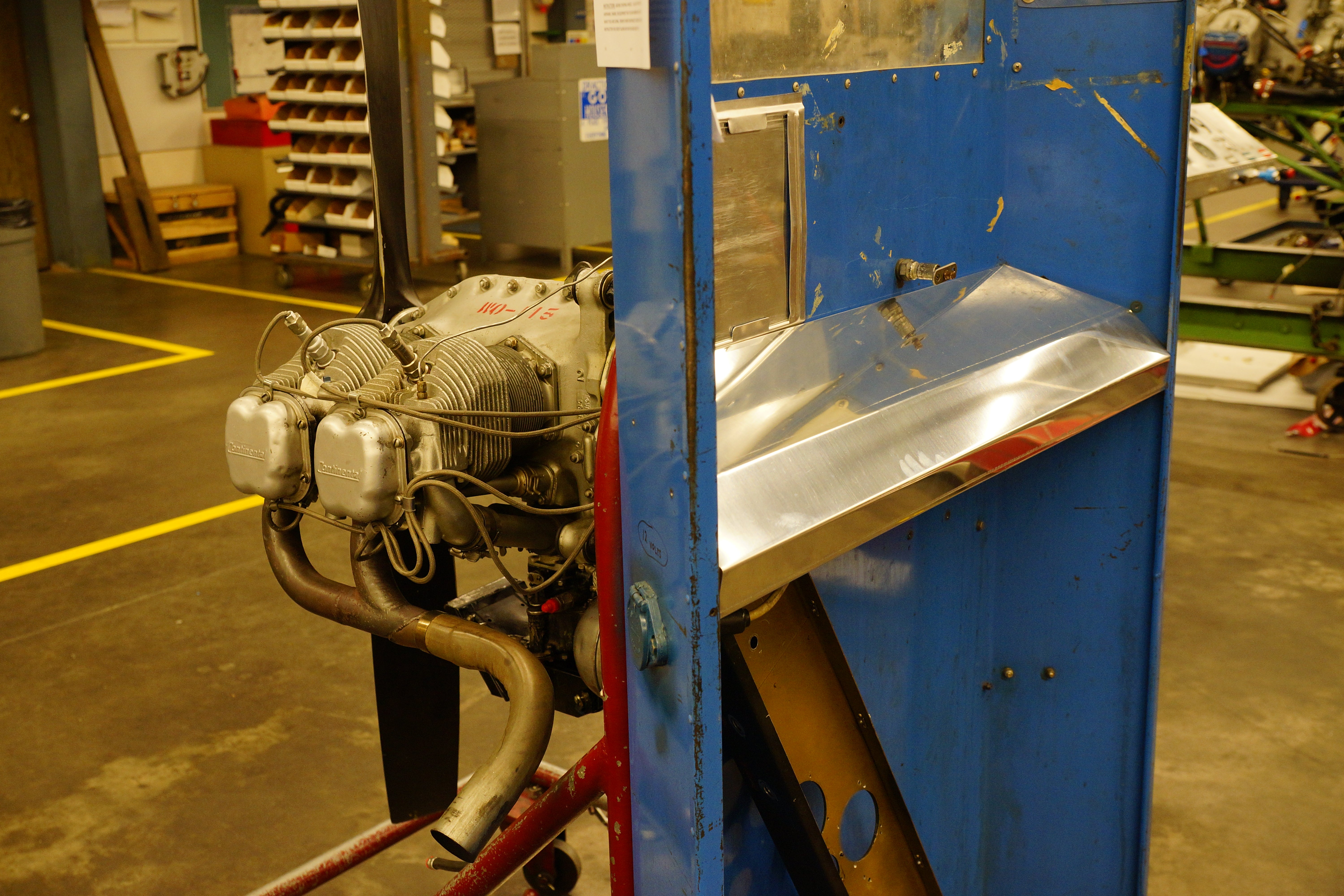

In my second quarter I learned circuit analysis and electronics, and in my third quarter I "overhauled" a Lycoming GSO-480 (which will never run again) and various sections of various jet engines (which also will never run again). This quarter, we took a perfectly good !!!error: Indecipherable SUB-paragraph formatting!!! (also known as an O-190), rebuilt its magnetos and carburetor, and assessed it for Stuff That Could Be Done Better.

The primer pump is marked "WIND SHIELD WASHER." Of course we kept it.

On an engine that hasn't left the ground for decades, and has only been serviced by students for the last forty years, you can find quite a bit of shoddy work. My instructor tasked me with repairing the ugly work, as well as installing new instruments and controls.

The barrel for the starter handle is the casing of an 18mm spark plug. We kept that, too.

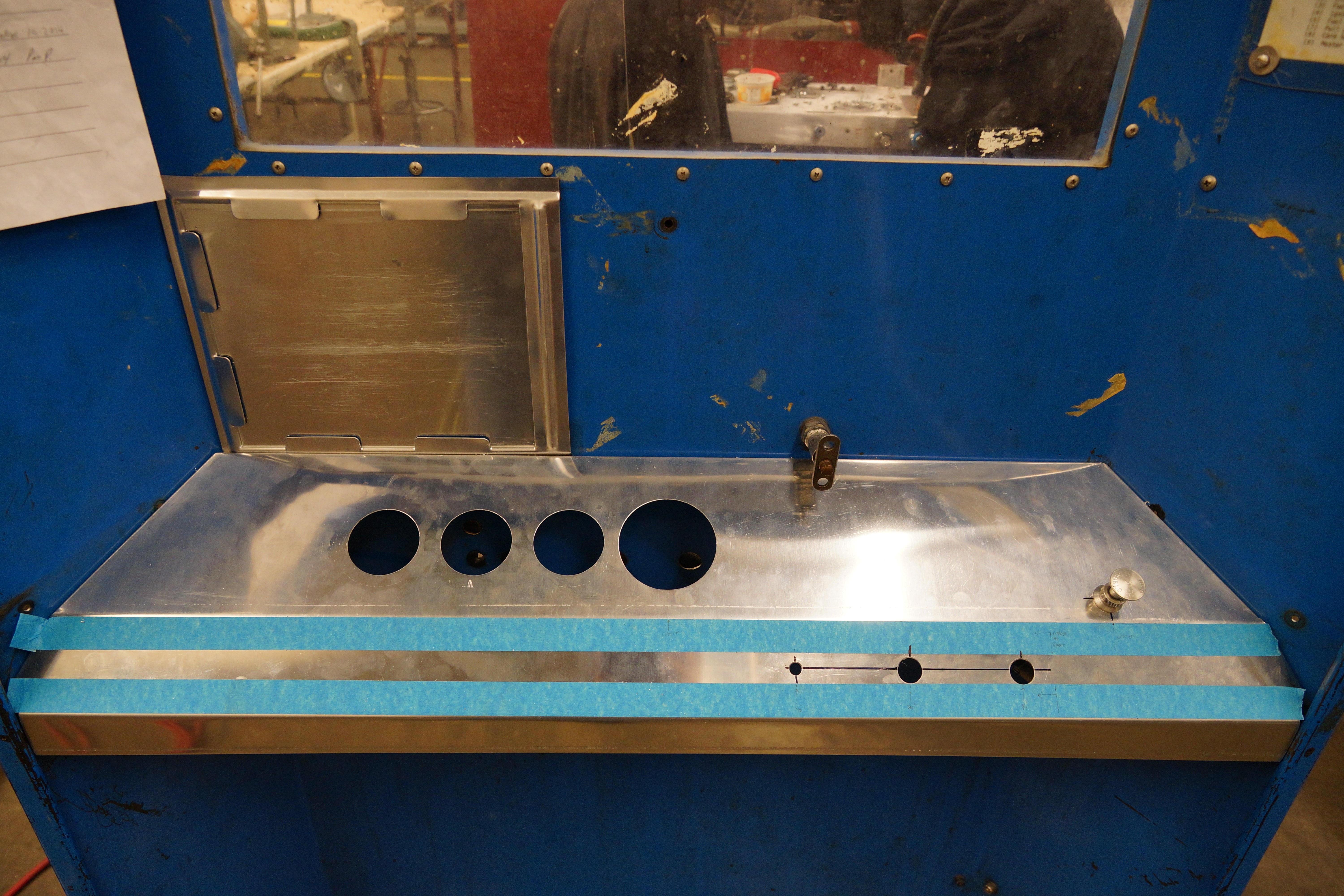

The first thing we assessed was where to put the new controls and instruments on our old control panel, or whether they would fit at all. Of course they wouldn't, so I got to build a new dashboard that would accommodate the new gear.

Every other engine's console looked like it was made by !!!error: Indecipherable SUB-paragraph formatting!!! .

The next step was to start stuffing new gear in and finding the routes that all the wires and hoses would go. We learned some hard lessons during this part, especially when it came to working tired and practicing new procedures on things you don't love before you work on parts you can't afford to foul up.

Two weeks learning new fabrication skills and applying them to a fever dream of trigonometry and—oh god, I have to cut holes in it now?

What followed was too fast, and too much work, to stop and get many process pictures, but it involved a lot of bold decisions and bravery tests—for a perfectionist, anyway. We installed the new instruments, new probes, new fuel lines, and plumbed all the leads that would run between them, and planned a layout for the electrical system that hopefully wouldn't make future students curse "the jackasses that made it this way."

With everything test-fitted, and all design and layout decisions finalized, it was time to remove the panel and paint it. I want to say we did a better job than two tired students should be able to do with a rattle can of wrinkle coat and a too-small paint booth, but we set the bar rather low, I'm afraid. Painters we are not.

It's wrinkle coat—another layer should just cover up the runs on the first layer, right?

At long last, we were able to get everything installed and tidied up. The wires all found their permanent homes, safely snugged away in fire sleeves and cushion clamps, and all the flexible hoses were secured to the frame with much improved access to the magnetos (for future students to remove and reinstall, and definitely not curse our names).

Yeah, it could have been packaged with more attention to keeping it compact, but in the end it is a teaching tool, and I wanted to make the wiring very clear and understandable.

For more pictures of the finished work, and the riveting tale of the "smoke test," !!!error: Indecipherable SUB-paragraph formatting!!! . Don't worry, the engine is running fine, now. Promise. I hope you enjoyed this tale, and seeing the transformation and preservation of a classic aviation engine. See you in the comments!

KatzManDu

> Kevin Barrett

KatzManDu

> Kevin Barrett

03/07/2015 at 05:29 |

|

I whole-heartedly approve this post.

The refreshed test stand looks very nice.

If you can overhaul the gearboxes on the GO-435/GO-480 series you can print money. It's a rare niche.

Cziggy

> Kevin Barrett

Cziggy

> Kevin Barrett

03/07/2015 at 09:36 |

|

I attended BCIT and took the gas turbine technician course and had the best time tearing down a small helicopter engine, a 20ft long military jet engine and an RB211. The work was incredible and long but so much fun. Very fond memories

Kevin Barrett

> Cziggy

Kevin Barrett

> Cziggy

03/07/2015 at 12:47 |

|

Nice! Does that program give you any kind of certificate? The FAA doesn't certify anybody for just turbines, that I'm aware of, so in our "Powerplant" classes we've been working with both recip and turbine engines. In just a year now I've completely torn down a GSO-480 and put it back together again, done compressor and hot section inspections on an Allison 250 and a J-52, stripped an old Franklin motor from a Bell 47 and removed all its accessories (the next class inherited that project...the pistons are rusted into the cylinders), and tinkered with fuel and ignition components on a JT-3C (still in its Boeing 707 nacelle!).

It might just be due to my school having mostly really ancient motors, but I think I'm leaning towards preservation and general aviation...

Kevin Barrett

> KatzManDu

Kevin Barrett

> KatzManDu

03/07/2015 at 12:50 |

|

Sadly, we did not do much with the gearbox of the GSO-480 besides pop it off of the front of the engine for the tear-down. For the engine we did complete dimensional inspection of every single component, but the transmission was just put on the shelf...I'll make a fuss next time my instructor brings me around to one.

orcim

> Kevin Barrett

orcim

> Kevin Barrett

03/07/2015 at 15:44 |

|

I like your style. Worrying about whether what you did was understandable or not. Like documenting code or writing it as self-documenting. That's a talent and pays dividends in the future (which you may never know about, but are there.)

KatzManDu

> Kevin Barrett

KatzManDu

> Kevin Barrett

03/07/2015 at 15:53 |

|

Roger that. Not hat many people use those engines anymore, but they exist and they're in some interesting aircraft. Note the 1st two look VERY similar but they are very different airplanes.

Kevin Barrett

> orcim

Kevin Barrett

> orcim

03/07/2015 at 20:28 |

|

Thanks! I have technical drawings of the console, but it's robust enough to take repairs and patches in the future of needed. I doubt it'll have to be made again or replaced. The extra facet provides more mounting options for long or short cables. On Monday I'm going to fix an electrical schematic to the frame, so that tracing wires in their bundles will be easier, still.

I'm not a new student. I'm not a kid. I've worked at big institutions before and I know the value of giving your best and looking out for "the next guy that works on it."

orcim

> Kevin Barrett

orcim

> Kevin Barrett

03/08/2015 at 00:41 |

|

If I was hiring, that's what I would be looking for. Now we just have to figure out a way to make that attitude and skill stand out on a piece of paper so the hiring person *knows* what they are getting.

I swear, resumes are going away and portfolios (like a graphic artist) are gonna be the deal.

Kevin Barrett

> KatzManDu

Kevin Barrett

> KatzManDu

03/10/2015 at 01:47 |

|

Nice! Those first two reminded me of the ERCO Ercoupe (but with a more conventional empennage), then that last one is wearing the same color as my very favorite Ercoupe, NC93716 . The Ercoupe was another (eventual) bearer of the little C-85 powerplant, but this one started with the punier C-75.